Die Level Services © 2021

MicroElectronicpackaging / AssemblySolutions Fast 4U

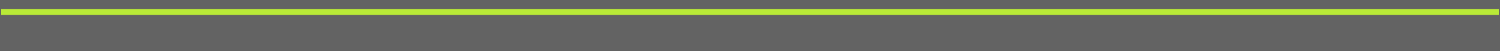

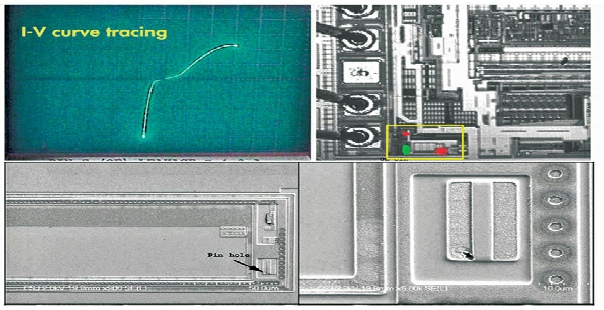

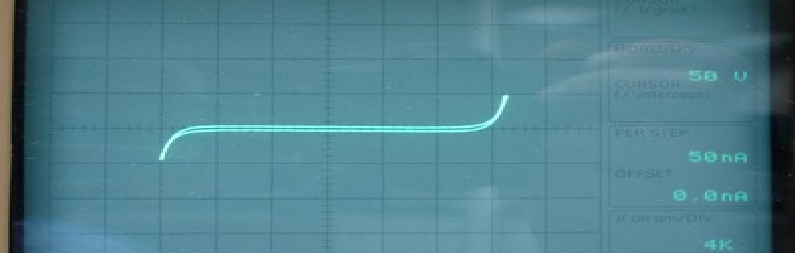

What is Curve Tracing?

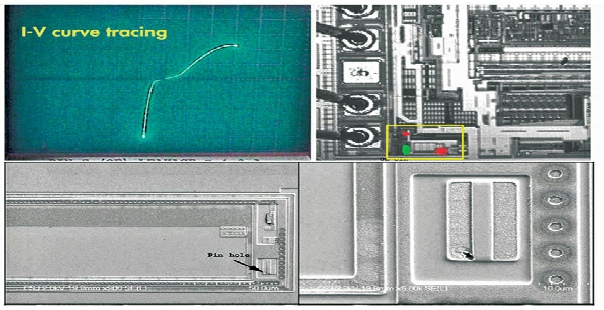

Curve Tracing is a widely accepted method for finding electrically damaged pins on IC chips. Die Level Services Team provides wide a range of solutions from opens and shorts testing on small devices all the way up to Powered curve trace and Latch Up testing on very complex multi power supply devices with thousands of pins.

Electrical Paths Testing

A curve tracer is usually used with two probes, one for each of the nodes that define the electrical path being characterized.

“Using our Failure Analysis services can help you improve product quality and can apply to a variety of manufactured products, components and materials, including metals, plastics, electronics, and more”.

Why Do Curve Tracing?

It is a simple test where the pins are grounded and each pin on the device is curve traced. Using Dimation’s curve tracing equipment. a known good device can be inserted and comparison curves can be acquired and compared to the DUT. This process of testing 2 devices and comparing to identify anomalous or failed pins.

Curve Tracing is a good method for Failure Analysis testing as a non-destructive test to objectively assess if electrical damage has occurred to the circuits (or pins) of a semiconductor IC devices.

Little needs to be known about the actual Function of an IC chip, the locations of the power pins and if the other pins are inputs, outputs or I/O pins is often all that is needed for a powered curve trace.

CURVE TRACING

Counterfeit Prevention, Removing the Lid from a Device/Package

Back to TOP

Back to TOP

Back to TOP

Back to TOP